Products

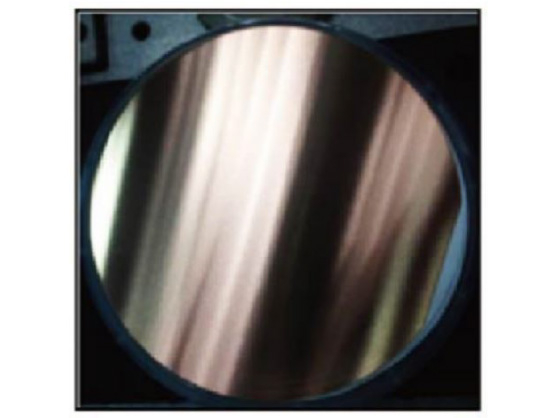

CMW Copper magnetic wafer

Intrinsic Magnetization Filmy thermal Conductivity Technology

In order to manufacture high performance gas cylinder, Ingentec study many composite metal and found copper magnetic wafer (CMW) has the excellent character of permeability, heat dissipation and chemical slicing can be widely applied in high power red LED, Micro LED and as the substrate. It can improve the mass transfer yield, shorten the process time and increase the LED die brightness and electric saving. It also can be applied in VCSEL (Vertical-Cavity Surface-Emitting Laser) as the substrate to solve the problem of heat dissipation and increase the emission distance and die brightness. More application is under developed.

PRODUCT INFOMATION

- Product Description

-

CMW Copper magnetic wafer

- Applications

-

Mini & Micro LED, VCSEL

- Feature

-

01

High thermal conductivity

Heat from LED chip could spread easily and increase LED efficiency and lifetime

02

CTE matching to GaN & GaAs

Without the warpage issue, CMW could increase the process yield rate because CTE of CMW is the same with EPI layer.

03

Ultra Thin Thickness

The thinness of existing product is around 0.15mm-0.2mm, but CMW could be achieved 0.05mm-0.1mm without polishing process further reduce the manufacturing cost.